- PRODUCTS

- Ultra High Molecular Weight Polyethylene (UHMWPE)

- UHMWPE Products with Vitamin E

- Acetal (Hostaform® MT®2U06)

- Radel® R-5500

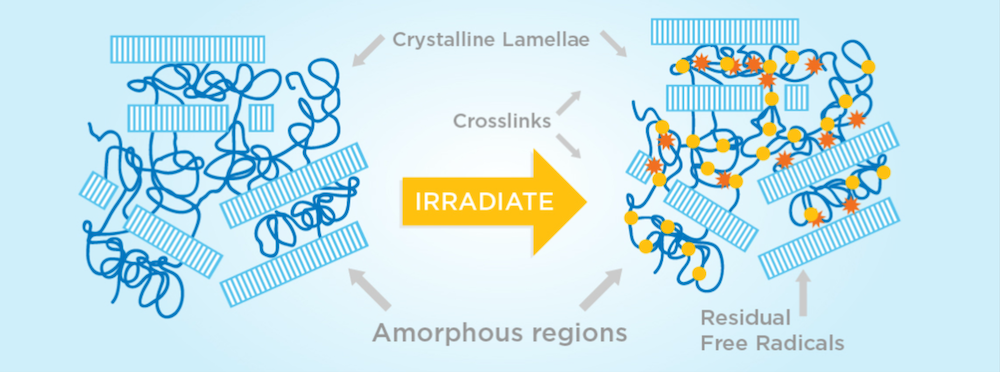

- Crosslinking & Crosslinked Polyethylene

- Direct Compression Moulding (DCM)

- Component Machining Products

Introduction

Recent developments at Orthoplastics have allowed for the addition of Vitamin-E into UHMWPE plastics.

The benefit of adding Vitamin-E to UHMWPE is the increase in lifespan of the medical implant, providing an obvious long term benefit to the patient. It has been scientifically proven that Vitamin E is an effective oxygen scavenger, and as a result of this, it leads to a reduction in oxidation after irradiation has taken place.